Road crews always know when a shift is going to behave. They can tell by the tone of the aggregate when the asphalt paver roll out smoother than planned. That’s something achieved by precision in the quarry. Specifically, it’s about the discipline behind the jaw, the one machine that quietly decides how much work everyone else will do later.

The crusher that writes the script.

Every stretch of road starts its life in a blast pile. But what turns rock into something roadworthy isn’t the explosion. It’s actually the compression.

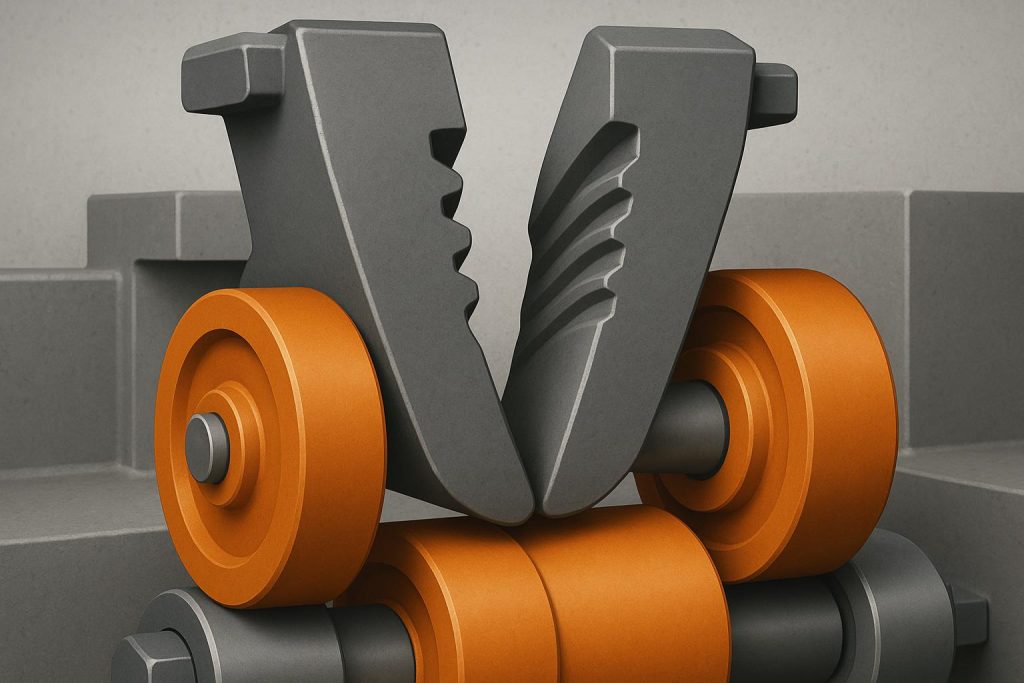

The jaw crusher does more than just break stone. It decides shape, texture, and ultimately, how the base will compact. When its settings don’t work properly, everything turns into extra work.

Aggregate plants operate under heavy cycles. You’ve got hot mornings, abrasive feed, and relentless tonnage. Under those conditions, even a slight change in the crusher’s closed-side setting (CSS) can tilt the balance between perfect interlock and a base that behaves like ball bearings. And when that happens, the next crew pays for it in roller passes, fuel, and time.

“Close enough” isn’t enough

Most crushers start well. But over a few thousand tonnes in, wear starts sneaking in. Liners are eroding, and suddenly “100 millimetres” means 115.

Operators are too busy chasing production quantity instead of quality, because of which they nudge the conveyor faster to hit targets, unaware that every extra lump will haunt someone else later.

A base with oversize material feels fine when it’s still loose. Once compacted, though, the voids between those big particles become tiny air pockets waiting to collapse. The soil compactor has to literally force them shut, often over-compacting the surrounding fines just to hit density.

That leads to a poor surface that starts to drum underfoot, with edges cracking sooner than expected. And before long, the roller crew are the villain for a problem that started miles before them.

The opposite is just as bad. Over-tightening the jaw can sometimes create too many fines. Moisture clings to them, and compaction becomes sticky instead of firm. Ultimately, the mat ends up spongy even before the asphalt arrives.

Operators can try to bake it flat with more passes as much as they like, but the structure underneath will never really bond.

Keeping the jaw honest

Modern plants can help themselves. Remote CSS adjustment, hydraulic toggles, and real-time pressure sensors let operators tune settings without stopping production. But none of that replaces attention. A good jaw needs eyes, not just software.

Routine inspections still save the day. Checking jaw plates for uneven wear, replacing liners before they become concave, and measuring output gradation every few shifts might seem like a lot, but trust me, you’ll thank yourself later.

Shape matters as much as size.

In hot climates like the UAE, for example, aggregates expand slightly during the day, then contract after dark. If the particles are flaky, they tilt and loosen, leaving micro-voids that even asphalt can’t fill perfectly.

But when the stone is cubical, those micro-shifts cancel each other out. The base behaves like one continuous mass.

That stability pays forward. The screed on a paver rides more evenly and joints close cleaner because the platform beneath isn’t flexing. Good crushing doesn’t just save roller passes. It saves the next layer’s patience.

Operators know their output

Good quarry operators develop a kind of sixth sense. They can hear if the gap’s changed a few millimetres just from the tone of the machine.

Some crews joke that they can tell which plant the material came from by the way the grader reacts. One setting makes the blade skate, another lets it bite. That kind of “fingerprint” is what separates consistent projects from the ones where everyone spends the week explaining soft spots to inspectors.

What good crushing really buys

When the feed is right, every part of the process works less hard. The paver lays smoother, the compactor stops fighting, and the crew clocks off earlier without guilt. Jobs finish clean because there’s nothing left to correct.

So the next time density readings hit spec on the third pass and the mat comes out glossy and true, remember it wasn’t just the surface team that nailed it. It was the jaw that really came through.

That’s what a disciplined jaw crusher does. It writes a smoother story, saves fuel, and lets the base earn its strength early. The finish everyone sees is really a reflection of the choices made at the quarry. Because when the rock is right, the rest of the job simply works.