An capsule filling machine is pharmaceutical equipment that is widely used in the pharmaceutical industry for filling empty capsules with various substances including medicine or nutrients.

The capsule filling machine has three types – full automatic, semi automatic and manual. The full automatic and semi automatic capsule filling machine have high productivity and fit for large scale capsule filling project. It is possible to fill all size of capsules with super big accuaracy up to 99,99%.

The manual capsule filling machine is suitable for individual usage with small capacity, mostly for personal use with special filling purpose for nutritional supplements and natural herbs.

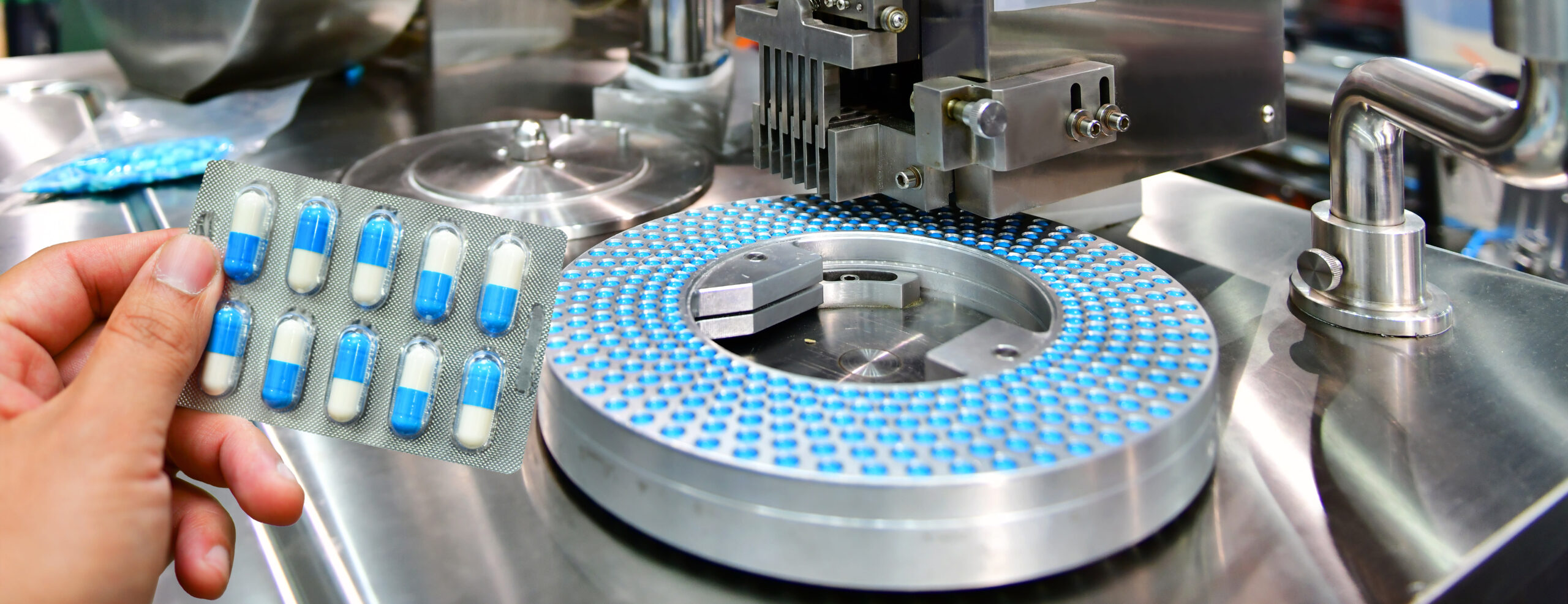

Filled capsules by the automatic capsule filling machine

And beyond all doubt, full automatic and semi automatic ones are of high degree of automation.

Best Features of Automatic Capsule Filling Machine

According to icapsulepack.com, with improved inner design turret and Japan imported beeline bearings, the automatic one has a longer usage-life and precise filling. Good lubricating condition for the working station cam that guarantees the cam slot has good inner lubrication system.

Increased pulverization oil pump pressure has extended the operation of the spare parts.

HIM touch screen that makes the automatic machine has a stepless timing with the frequency-conversion.

The better sealing performance is ensured from a single movement in the lower and upper parts with two-lip seal.

Both the Chinese traditional medicine and the Western medicine can be filled by the automatic capsule filling machine with large capacity. Protector equipment for the operator and the machine. Automatic pause equipment when it is lacking for the material.

Steady and safe working condition

The mashine has additional feuture of blowing, which guarantee clean working conditions.

Advantages of Automatic Capsule Filling Machine

- Making unique capsules

- Achieving mass production

- Cost-effective

- Easy to operate and maintain

- Owning upgradable machinery

- Eliminating materials wasting

Industries where these machines are widely used:

1.Pharmaceutical company

2.Drug store

3.Food industry

4.Healthcare industry

5.Cosmetic industry

Seven critical steps for the automatic capsule filling working process

Step1: Capsules rectification

There is a special mechanism that spread the capsules on the holes.

And all the capsules need further rectification as it may be body end downward or cap end downwards when falling.

Step Two: Separating the Body from Caps

The diameter of the capsule body and caps are different and with vacuum the capsule will be separated.

Next, the capsule caps will be stuck to the upper part of the capsule tray and capsule bodies will go downwards.

Step Three: Filling Medication

Once the filling rod is lifted from the hole, the box with the powder will go around and all the powder there will go into the mold holes.

Step Four: Wasted capsules rejection

A big advantage of the machine is if the capsule cap is not removed from the capsule body, it will be removed automatically out of the mold and the capsule will go to the collecting bags.

While the capsule caps and bodies that are separated will be transferred to the next station.

Step Five: Capsule locking

The baffle plate above the capsule tray and the pin below the tray begin to move to make the capsule be locked.

Step Six: Filled capsuled Locking

The capsules will be outside the capsule tray. Later compressed air will remove the ejected capsules in the exit.

Step Seven: Cleaning

There is a special powerful vaccum system that will suck into the cleaner and will ensure that the hole of the mold is clean. This way the mashine will be ready for the operation.

Necessary equipment for the automatic capsule filling machine

A complete automatic capsule filling machine production line should include the granulator crusher , vibrating screen and fluid bed dryer to preparate the to be filled powder.

Then there should be the automatic capsule feeder to load all empty capsules .

Capsule polisher

Then after the filling process,the drying system,capsule polisher to dealing with the filled capsules to make which have more appealing appearance.

At the final stage ,there is the packaging ,there need the capsule blister packaging machine to pack the sorted capsules and the cartoning machine to cartoning pack that .

Let’s go further explaining the capsule filling machine

Full automatic capsule filling machine

NJP-2500 Full automatic capsule iflling machine

A full automatic capsule filling machine is a device that you can use to fill empty capsules with a variety of substances. Besides,a full automatic capsule filling machine has large output, accurate filling dose, good adaptability to drugs and empty capsules, stable, high degree of automation.

Semi automatic capsule filling machine

CGN-208D1 Semi-automatic capsule filling machine

A semi-automatic capsule filling machine is a machine that depends on automatic and manual parts to fill empty capsules.

A few professionals will be needed to assist the operation of the manual parts of the semi automatic capsule filling machine.

Manual capsule filling machine

A manual capsule filling machine is a device that you can use it to fill empty hard gelatin capsules manually.

It would be liked by someone who loves to fill fill nutrients and medicine on a small scale like inside their home.

Major manufacturers of the automatic capsule filling machine around the global

Hubei Aipak Pharmaceutical Machinery Co.,Ltd.

The company was set up in 2012,is a global supplier of pharmaceutical, food packing and cosmetic equipment.

With more than 15 years’experience in the industry, Aipak has over 15 subsidiary factorie,has now been one of the largest hard capsule filling machine suppliers in China.

All pharmaceutical equipment from the company meet cGMP and CE requirements. And most automatic capsule filling machine sold from the company worldwide ,such as the USA,Europe,Mid-east and Germany.

Presently,Aipak automatic capsule filling machine has been well used by all its customers.

LFA Machines

The company was started in 2009, initially focusing on small tablet presses. These presses were used in different niches such as chemical manufacturing; compound pharmacies and others. The company decided that it is hard to specialize in everything.

With industry experience, LFA machines have developed so many other pharmaceutical machineries, like capsule polisher and high shear mixer granulator.