The rise of the LFP battery is due to its remarkable safety, long life, and cost-effectiveness, rooted in its stable Lithium Iron Phosphate chemistry. However, unlocking the full potential of these benefits depends entirely on a sophisticated LFP battery integration process.

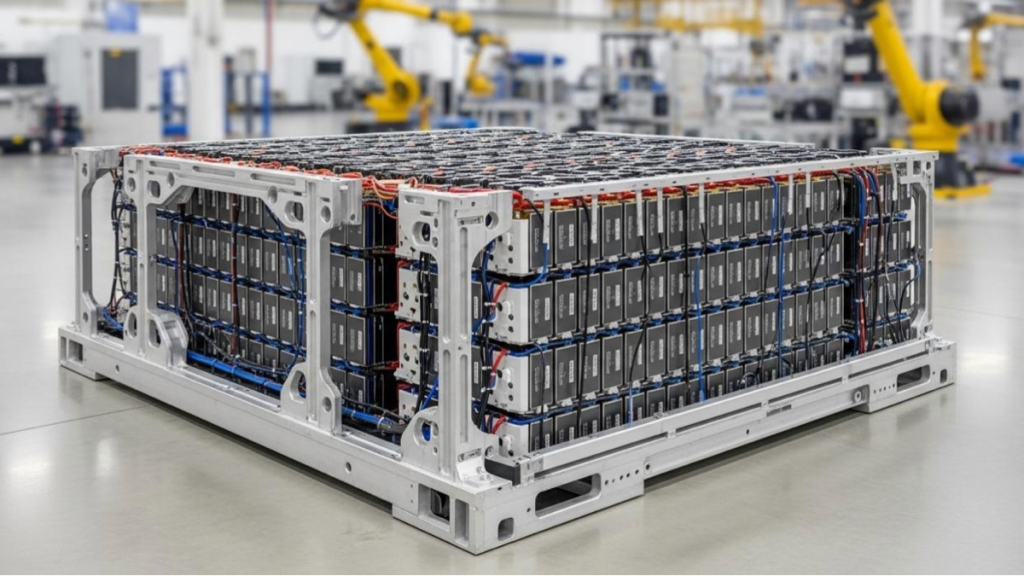

The journey from individual raw LiFePO4 cells to a powerful, grid-scale system is a multi-layered engineering challenge. Proper assembly is the key that transforms the inherent chemical advantages of LFP into real-world performance, determining the final system’s efficiency, density, and reliability.

Level 1: Cell-Level Integration – The Foundation

The foundational building block of modern LFP systems is the prismatic LFP cell. Its rectangular form is ideal for stacking, but how these cells are connected and arranged has cascading effects on performance and serviceability.

Connection Methods

- Bolted Busbars: This method uses screw terminals to fasten conductive busbars, offering high serviceability. A single faulty cell can be replaced, making it ideal for prototypes and field-serviceable systems. However, these connections may have higher resistance and can loosen over time without proper torque.

- Laser Welding: Dominant in high-volume automotive manufacturing, laser welding creates a permanent, low-resistance bond that is highly resistant to vibration. The process is fast and suited for automation. Its major drawback is permanence; a single cell failure often requires replacing an entire welded module.

- Conductive Adhesive: An emerging alternative, these specialized adhesives provide mechanical, thermal, and electrical connection in one step. This avoids the high heat of welding, but its conductivity is generally lower and long-term durability is still under development.

Arrangement Strategies

How LiFePO4 battery cells are configured mechanically is critical for managing their tendency to swell during cycling.

- Stacked with Compression: Applying constant, uniform pressure across the flat faces of prismatic cells is essential for a long life. This is achieved by clamping cells tightly within a rigid housing or using tensioning straps, which maintains internal contact and ensures proper ionic flow.

- Parallel-First Configuration: To build the desired voltage and capacity, the preferred electrical arrangement is to first connect cells in parallel (to form blocks) and then connect those blocks in series. This “Parallel First, Then Series” approach allows the parallel-connected cells to naturally self-balance, reducing the strain on the Battery Management System (BMS).

Level 2: Module-Level Assembly – Building the Core Unit

The intermediate step of assembly has evolved significantly, moving from traditional modules to more integrated, efficient designs.

- Standard Modules: The conventional method involves assembling cells into a protective module housing. While this offers protection and simplifies final pack assembly, the extra housing, connectors, and wiring add significant weight and volume, reducing the pack’s overall energy density.

- Hot-Swappable Modules: A niche but important design, hot-swappable modules are self-contained, plug-in units that can be quickly replaced without system downtime. This prioritizes maximum uptime and rapid service for mission-critical applications like data center backups or 24/7 automated guided vehicles.

- Cell-to-Pack (CTP): This revolutionary approach eliminates the module level entirely. Large prismatic cells are integrated directly into the final battery pack, dramatically increasing space utilization and pack-level energy density. CTP is the key strategy that allows LFP batteries to overcome their historical disadvantage of lower cell-level energy density and compete directly with NMC packs in long-range EVs.

Level 3: System-Level Integration – The Final Application

The final system architecture is tailored to the specific needs of the end-market, from a single home to an entire utility grid.

- Rack-Based Cabinets: For Commercial & Industrial (C&I) use, the dominant design is a modular, rack-based cabinet. These systems allow businesses to make a scalable investment, adding more battery packs to a rack as energy needs grow. They are primarily used for economic applications like peak shaving and demand charge reduction.

- Containerized Systems (ESS): To reach the megawatt-hour scale needed for utility projects, fully integrated systems are deployed in standard shipping containers. A containerized ESS is a turnkey solution including batteries, power conversion, HVAC, and fire suppression, allowing for rapid deployment with minimal on-site construction. These are used to store renewable energy and stabilize the power grid.

- All-in-One Units: The residential market favors a consumer-centric, all-in-one product that combines the LFP battery, an inverter, and an intelligent energy controller in a single, sleek enclosure. These systems function as a complete home energy ecosystem, managed by mobile apps to optimize solar self-consumption, save money with Time-of-Use rates, and provide backup power.

The Solution: Great Power’s LFP Cells

Success at every level of LFP battery integration starts with a quality foundational component. Great Power manufactures high-quality raw LiFePO4 cells that serve as reliable building blocks for this wide range of applications. Models like their 100Ah prismatic cells feature very low internal impedance (≤0.5mΩ) and a long cycle life of over 4,000 cycles. The low impedance minimizes heat and energy loss, while the high cycle life ensures a low total cost of ownership. By providing a consistent and high-performing cell, Great Power enables the advanced integration strategies that are making LFP a dominant force in the market.

Conclusion

The success of LFP technology is a story of sophisticated innovation beyond just its core chemistry. While the inherent safety and low cost of the LFP battery are crucial, it is the advancements in integration that have unlocked its true potential. Innovations like Cell-to-Pack (CTP) and Cell-to-Chassis (CTC) have solved the energy density challenge, while tailored system designs for residential, C&I, and utility markets have met specific customer needs. As the technology matures, the competitive edge is increasingly defined not by the cell alone, but by the intelligence and engineering of the complete, integrated system built around it.