Most mines sit far from any grid, so crews haul mining generators and string long lines through rugged terrain. Diesel then travels hundreds of kilometers by truck, so every oil price spike or delay hits the balance sheet. On the other hand, when a grid spur exists, the long feeders and punitive weather bring voltage dips and blackouts that stop crushers cold.

All that makes a reliable mining power supply elusive and pushes sites toward hybrid or renewable options. This article will show how hybrid power systems offer a more efficient, cost-effective solution.

Hidden Cost of Traditional Diesel Power in Mining

While diesel generators remain a common choice in mining, their full cost often extends far beyond fuel and equipment.

Expensive and Risky Fuel Logistics

Remote mines use bulk diesel deliveries, and every extra kilometer of rough track shows up on the fuel bill. ABB’s modeling shows those deliveries add storage headaches and can push electricity costs to about US$300 per MWh[1]. Australian logistics analysts add that long distances, expert haulage, and volatile pump prices keep transport costs rising and supply chains fragile.

High Maintenance Needs and Equipment Downtime

When a haul truck or excavator sits idle for repairs, Cummins estimates the loss can top thousands of dollars per hour[2]. Besides, according to ABB, maintaining a diesel generator fleet with six operational units and one spinning reserve results in an annual O&M cost of approximately US$1.7 million. Oil and filter changes eat into shift time, too, eroding the mining power supply budget.

Poor Fuel Efficiency under Variable Loads

Diesel gensets perform optimally at near 70-80% load[3]. Below that range, the liters-per-kilowatt figure climbs fast. Excalibur and ABB both note that partial-load running—common when extra units stay online as a reserve—wastes fuel and speeds wear. That inefficiency burns more diesel for the same work while inflating the complete mining power supply cost curve.

Rising Regulatory Pressure on Emissions

US Tier 4 rules already slash particulate and NOx from nonroad diesel engines by approximately 90%[4], and California is sketching even tougher Tier 5 limits. Underground operations must also meet Mine Safety and Health Administration engine-approval and ventilation rules, which adds further compliance costs. Australia is considering broader curbs after finding off-road diesel emits 5% of its CO₂ and could rise 27% by 2028 if unchecked[5].

As regulations tighten and compliance costs rise, mining operators are under increasing pressure to adopt cleaner, more efficient power solutions.

How Hybrid Systems Redefine Mining Power Supply

As the limitations of diesel become harder to ignore, hybrid systems are emerging as a more adaptive and cost-effective solution for modern mining operations.

Battery-First Cuts Generator Hours

In a hybrid setup, the battery fires first, soaking up sudden load swings and acting as a spinning reserve. For example, at the Granny Smith gold mine, a 2 MW battery lets crews shut down thermal units during steady demand while trimming runtime and fuel. That battery-first habit is redefining the mining power supply by cutting both cost and carbon.

Solar Covers the Daytime Shift

When the sun is up, PV carries most of the load, enabling batteries to recharge instead of engines running. The array can meet most of the mine’s daytime demand, backed by a battery solution that smooths cloud dips. Those daylight kilowatts save millions of liters of fuel every year.

Modular Kits Move with the Mine

Hybrid power systems now ship in containerized modules that drop in by truck or barge. Some brands even market “plug-and-play in four hours” microgrids, handy for new pits or fast expansions.

Smart Control Keeps the Balance

Energy management software coordinates each power source to ensure optimal load sharing and prevent unnecessary strain. The controllers can shift the spinning reserve into storage and intelligently share the load between gensets and batteries while increasing efficiency.

Where Hybrid Power Systems Work in Mining

Hybrid power systems aren’t one-size-fits-all—they adapt to the diverse and demanding environments found across mining operations.

Remote Mining Camps

Off-grid mining camps are turning to containerized hybrid systems that combine solar input, battery storage, and diesel backup. Batteries handle overnight or low-load demand, while generators only run when needed. This setup cuts fuel consumption, reduces delivery frequency, and maintains steady power in isolated or extreme environments.

Exploration Drill Sites

Land-based exploration rigs are adopting hybrid power systems that pair energy-storage packs with gas or diesel generator sets. Meanwhile, a system can power the rig draw-works from batteries during peak loads. They recharge while the bit is turning, which helps cut fuel use and engine wear on short-lived drill pads.

Temporary or Mobile Operations

When a pit is relocated or a project needs standby power for just a season, trailer-mounted mobile microgrids roll in with diesel, solar, and storage pre-wired, plug into the site in hours, and roll out again once the job is done.

Off-Grid Processing Facilities

High-demand processing sites far from the grid require stable, continuous power. Hybrid systems help meet this need while reducing diesel dependence. At Egypt’s Sukari Gold Mine, a 36 MW solar farm and 7.5 MW battery now feed the mill alongside legacy diesel. That saves fuel, delivers a stable mining power supply for 24/7 crushing, and leaches far from any grid[6].

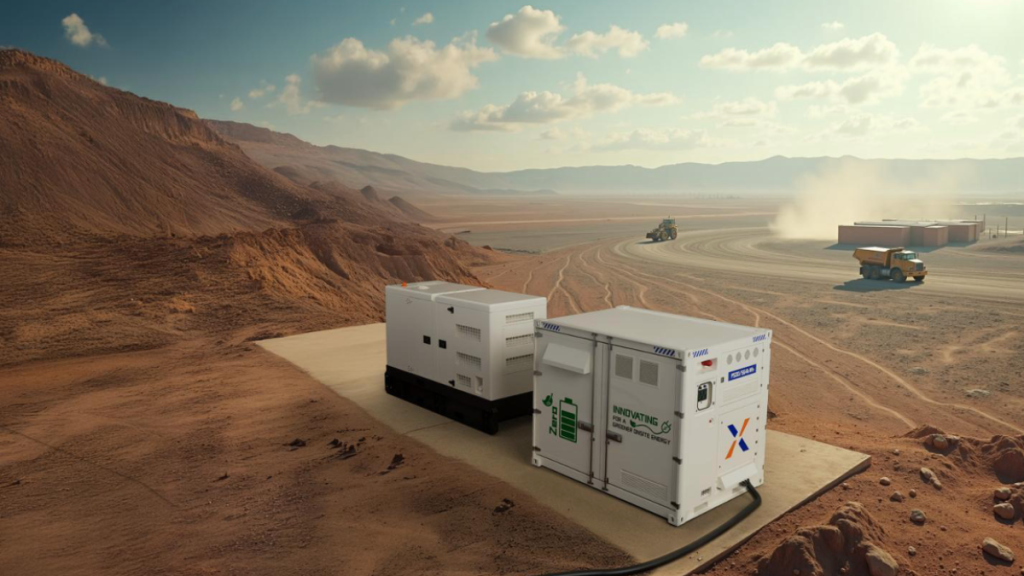

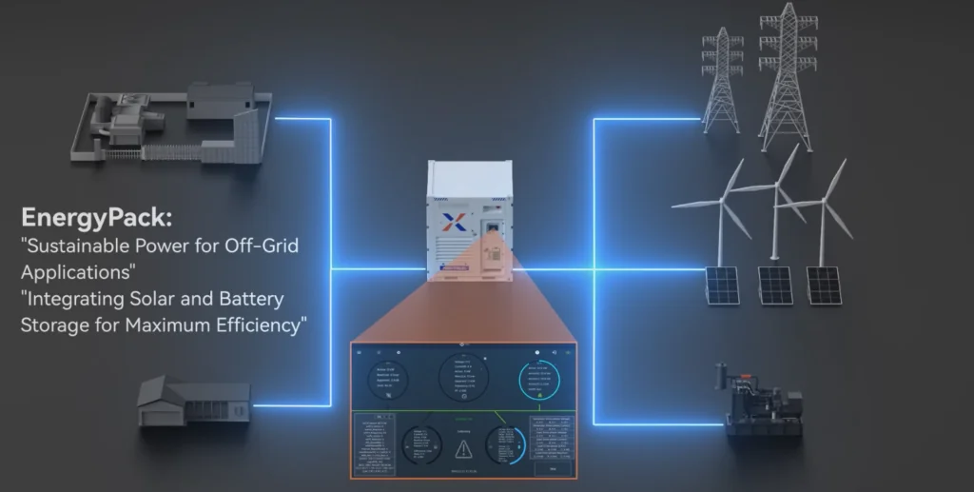

Foxtheon Hybrid Power Solutions for Mining

From remote gold mines to off-grid processing plants, hybrid systems are already reshaping how mining sites stay powered. But what does that look like in practice?

Foxtheon offers hybrid power systems purpose-built for the rugged demands of mining. Their solutions combine diesel, solar, and advanced battery storage to reduce fuel use, lower emissions, and deliver consistent performance—even in the most remote locations.

For mid-size mining sites with drilling equipment, conveyors, or water pumps, the EnergyPack P200 (188 kVA / 188 kWh) delivers stable power with reduced generator runtime. For large-scale operations running crushers, mills, or ventilation systems, the EnergyPack P500 supplies up to 500 kVA, meeting peak loads while significantly reducing diesel reliance.

Both EnergyPack P200 and P500 feature Foxtheon’s FoxMind system to smartly balance diesel, battery, and solar power, ensuring mining sites get efficient and reliable energy tailored to changing demands.

Choosing the right mining power solutions is key to unlocking efficient, cost-effective off-grid power supply. Foxtheon’s EnergyPack lineup makes it easier than ever to power your mining operations sustainably.

Reach out to Foxtheon today to explore how they can support your mining projects.

References

- [1]. Reducing Energy Costs and Environmental Impacts of Off-Grid Mines. Available at: https://hybridpowersystems.org/wp-content/uploads/sites/9/2018/05/4B_2_TENE18_007_paper_Bitaraf_Hamideh.pdf. (Accessed on June 27, 2025)

- [2]. Digging Deeper: Reducing machine downtime in mining. Available at: https://www.cummins.com/news/2021/03/23/reducing-machine-downtime-mining. (Accessed on June 27, 2025)

- [3]. Maximizing Diesel Generator Efficiency and Runtime: Proven Strategies. Available at: https://www.enee.io/post/maximizing-diesel-generator-efficiency-and-runtime-proven-strategies. (Accessed on June 27, 2025)

- [4]. USA: Nonroad Diesel Engines. Available at: https://dieselnet.com/standards/us/nonroad.php. (Accessed on June 27, 2025)

- [5]. Work to regulate one of Australia’s biggest sources of carbon dioxide stalls, FoI documents reveal. Available at: https://www.theguardian.com/australia-news/2024/nov/12/work-to-regulate-one-of-australias-biggest-sources-of-carbon-dioxide-stalls-foi-documents-reveal.(Accessed on June 27, 2025)

- [6]. Juwi Awarded Contract to Build World’s Largest Offgrid Solar Hybrid Project in Mining Industry. Available at: https://www.renewable-energy-industry.com/countries/article-5878-juwi-awarded-contract-to-build-worlds-largest-offgrid-solar-hybrid-project-in-mining-industry. (Accessed on June 27, 2025)