In the modernized manufacturing world, staying ahead requires understanding the nuances of rapid tooling. There are two main types to consider: direct rapid tooling and indirect rapid tooling. There are some differences between these methods to cater to your demands before starting manufacturing. It is worth understanding the distinctions between direct and indirect rapid tooling. Let’s take a look!

Understanding the Basics: Definition of Direct and Indirect Rapid Tooling

Direct and indirect rapid tooling are two sides of the same coin. They all belong to the rapid tooling technology, but each type has its unique characteristics.

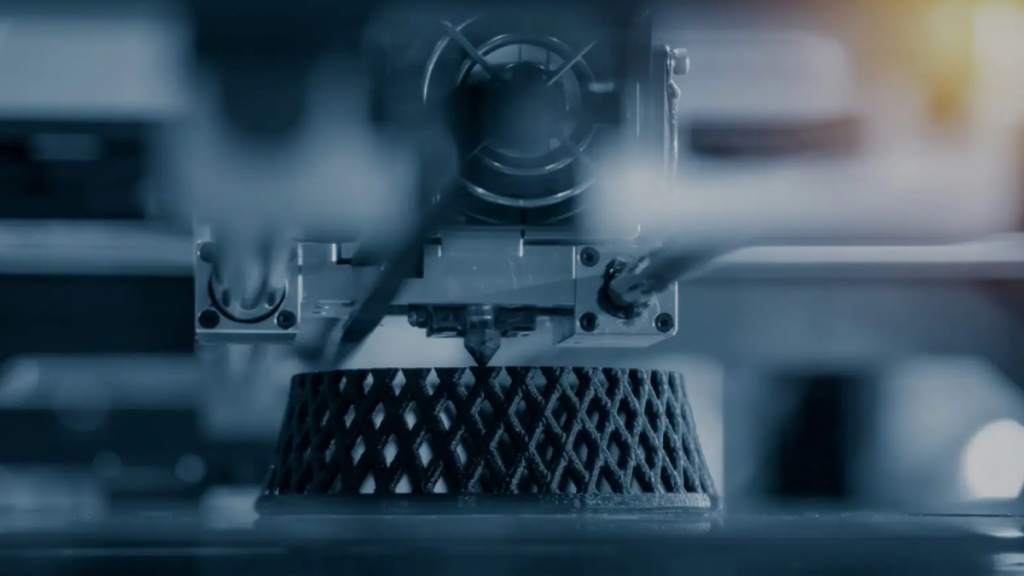

1. Direct Rapid Tooling

Direct rapid tooling refers to a manufacturing process in which molds are produced directly from digital design files without the need for intermediate steps or the creation of physical patterns. The primary objective of direct rapid tooling is to accelerate the tooling production process by minimizing the traditional steps involved in creating molds, such as pattern making and intermediate tooling. As a result, direct rapid tooling often delivers fast productions.

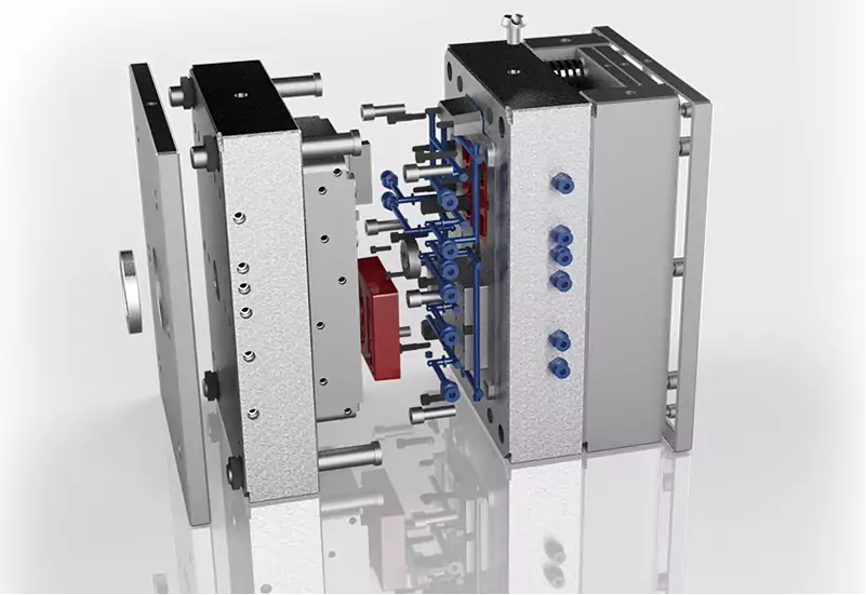

2. Indirect Rapid Tooling

As the name suggests, indirect rapid tooling has a more complicated manufacturing process. It involves the creation of molds through intermediate steps rather than producing directly from the files like CAD. Indirect rapid tooling is often employed in scenarios where the order needs more intricate designs, a variety of materials, or a quite large production volume.

First Difference: Time

When comparing Direct Rapid Tooling and Indirect Rapid Tooling, the critical difference is the time and production efficiency. As mentioned above, Direct Rapid Tooling streamlines the process without the pattern, which delivers a remarkable speed. This method makes it optimal for scenarios demanding swift turnaround and producing multiple molds. However, a small number of molds could be used as prototypes directly after the production.

Conversely, Indirect Rapid Tooling may take longer to complete the tooling process compared to Direct Rapid Tooling because it needs time to produce a master pattern. Yet more molds can be produced from it. In turns out, this method can produce more prototypes, which improves manufacturing efficiency.

Second Difference: Manufacturing the Complex Design

When it comes to intricate designs, Direct Rapid Tooling may not be the ideal choice. While rapidly in its production, it might not align seamlessly with the nuanced requirements of projects characterized by intricate geometric patterns or highly detailed features.

In contrast, the Indirect Rapid Tooling emerges as a perfect solution for demanding finesse in handling intricate designs. During manufacturing the master pattern, producers can ask the intricate details at these intermediary stages, ensuring that the final mold accurately captures the complexity of the intended design.

Third Difference: Cost and Durability

For Direct Rapid Tooling, it is generally deemed cost-effective. Nevertheless, the rapid production may bring the less durable mold to the future use. Balancing the cost-effectiveness of Direct Rapid Tooling is a strategic consideration when starting manufacturing.

Indirect Rapid Tooling proves to be a cost-effective solution when soft tools are in play. However, it’s crucial to note that the scenario changes when dealing with hard tools. Using harder materials may escalate the overall cost, emphasizing the need for a nuanced approach depending on the tooling requirements. The trade-off, though, lies in the exceptional durability that Indirect Rapid Tooling brings to the table. The robustness of the molds produced through Indirect Rapid Tooling ensures prolonged tool life and resilience in the face of demanding manufacturing conditions.

Introducing CS Molding: Your Rapid Tooling Partner

For your fast rapid tooling, CS Molding can be a reliable partner capable of handling both direct and indirect rapid tooling. Their commitment to fast delivery, superior quality, and competitive pricing makes them reputable in the industry.

1. Fast Delivery

CS Molding’s extensive inventory and precision machines enable the production of rapid parts with short lead times, ensuring timely delivery to any location worldwide.

2. Best Quality and Competitive Price

With expertise in cost-saving solutions, CS Molding is s professional in the prototype service industry that can deliver high-quality parts at competitive prices. Their shared mold base system reduces tooling costs by 30-50% compared to traditional production methods.

3. Multiple Material Options

CS Molding offers a diverse range of material options, such as aluminum, epoxy resins, and silicone. It ensures that any material suitable for injection molding can be utilized in rapid tooling, especially in indirect rapid tooling. Besides, their experienced engineers can assist in selecting the right material for your project if you have any doubts about the rapid tooling service.

Conclusion

In conclusion, the choice between direct and indirect rapid tooling depends on the specific needs of your project. With over 10 years of experience in the prototype service industry, CS Molding is now a trustworthy partner for businesses seeking efficient, cost-effective, and high-quality solutions. Here, you can receive the best quick prototyping, compression molding, plastic injection molding and more services about molding in order to cater for your specific needs. If you are interested, please contact CS Molding for more information!