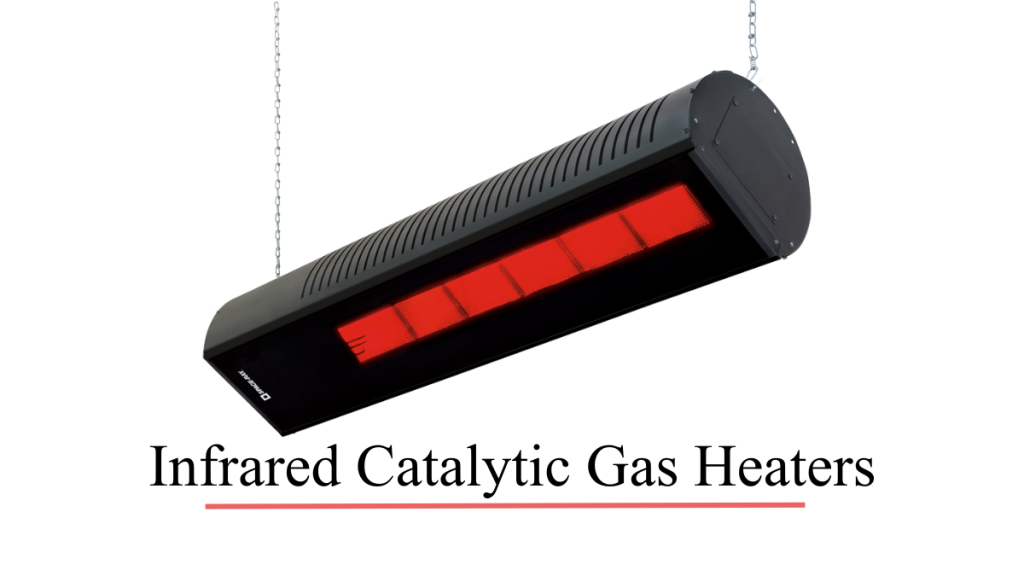

Infrared catalytic gas heaters provide heat without a flame. They are used for high temperatures in industries. Here’s some more information about them.

Using furnaces and coal for heating purposes in modern-day industries can be somewhat surprising for one to hear. In the new age, various modern technologies, which serve the purpose in less time than such complex and heavy machinery are available.Infrared catalytic gas heaters, or INFRACAT for short, are a core member of the modern appliances used in industries. Despite being an old prospect, it has become an integral part of many commercial systems globally.

Reasons To Use INFRACAT

History of Catalytic Heaters

The concept of using catalytic gas heaters is quite old in the industrial field. Yet, its practical uses have enabled it to remain one of the most successful thermal treatment processes in the world. Catalytic heating was introduced to the world a few decades ago. But it still remains an efficient method because of its functioning.

Principle

INFRACAT uses an already heated element, which is known as the catalyst, to create a chemical reaction between two other elements: the combustible heat flowing in, and the oxygen present in the atmosphere. Surprisingly, no flame is needed to initiate the process, and the reactions do not produce a flame either. Because of the catalyst’s properties, INFRACAT is able to provide temperatures from 180°C to 550°C.

Heat energy is released from the catalytic gas heaters in the form of infrared rays. Because these rays are not absorbed by air, they only provide energy to the material that absorbs them. Through this principle, these heaters provide the much-needed energy savings required in industries. The specific heat absorption also aids in quicker and better-quality treatment.

Uses

The biggest use of these machines is in the oil and gas industries. Because of their ability to provide a steady flow of heat, INFRACAT is a great option where heat is required in controlled amounts over a period of time. Large-scale industries use natural gas or propane for these heaters.

Why You Should Install An INFRACAT Instead Of Other Systems

Pros:

Catalytic gas heater is a guaranteed energy-saving appliance. Due to the technology employed in the design, these machines are able to start up within ten minutes. Due to faster start-up and treatment, the amount of resources that it saves is quite valuable.

These heaters are available in many different models. People have different requirements from a certain resource. Therefore, the INFRACAT is available in various models, which range in their specifications. From size to power consumption, it gives significant variability in each of its models.

As compared to other appliances, INFRACAT also comes with a manual or thermostatic safety valve. This means that either the user can turn it off by will, or the heater will stop automatically at a specified temperature. Therefore, this heater is a better option for places that employ thermal treatments.

INFRACAT devices do not employ combustion of any type. Therefore, they do not produce harmful gasses for the environment. They work without a flame, so they are completely safe to use with no hazards.

The catalyst in the heaters also reacts with volatile organic compounds. All alcohols, solvents, and other substances harmful to the environment are converted into water vapor and harmless gasses after contact with the catalyst, rendering these devices a potent replacement for combustion appliances.

Cons:

These machines take a lot of time to cool down, so it may take a while before using them again.

A possible leakage from the natural gas pipes may cause carbon monoxide poisoning. Therefore, catalytic gas heaters require a site with good ventilation.