In the high-precision world of plastic injection molding, creating a perfect part is a multi-stage process. While phases like injection and cooling are critical, the final step—ejection—ultimately determines the quality and usability of the finished product. An effective mold ejector system ensures that the solidified part is removed from the mold cleanly, efficiently, and without damage. This crucial mechanism directly impacts part quality, cycle time, and overall manufacturing cost.

What Is a Mold Ejector System?

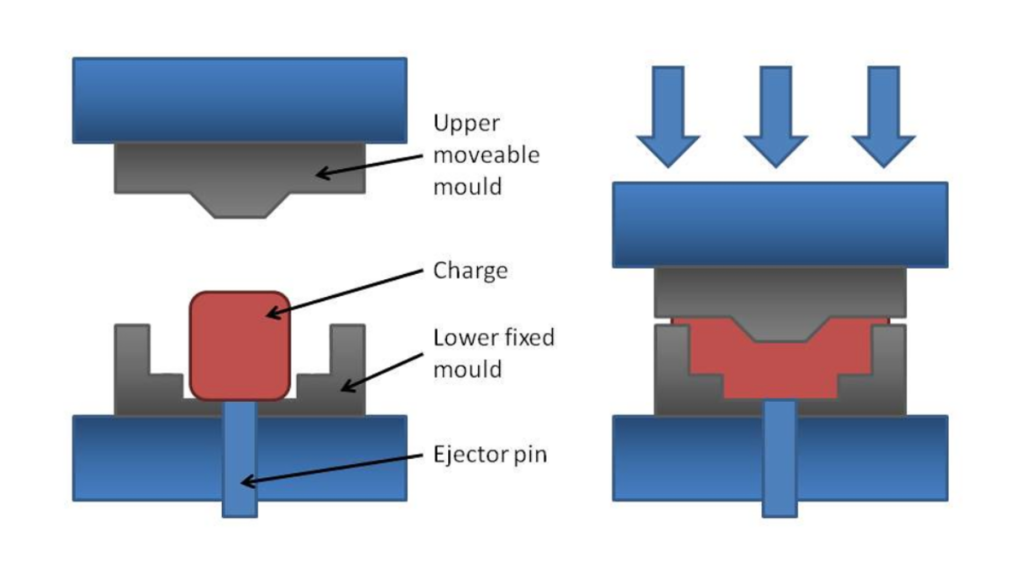

A mold ejector system is a mechanical assembly housed within the B-side (core or moving half) of an injection mold. Its purpose is to apply a controlled force to push the solidified plastic part out of the mold cavity after the mold opens. This is achieved through a coordinated sequence of movements involving several key components that ensure the part can be released efficiently without damage.

Common Ejector Components in Injection Molding

Ejection systems are not one-size-fits-all. They are composed of various parts, each designed for specific applications. The most common components include:

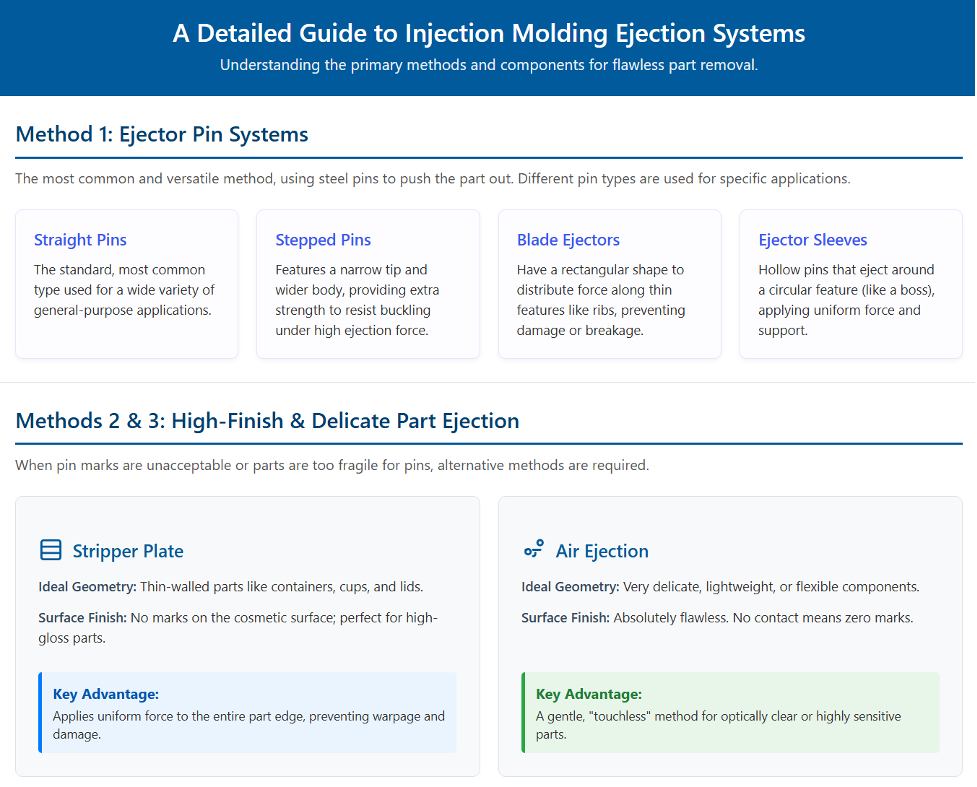

- Ejector Pins: The most widely used and cost-effective ejection components. These are cylindrical steel pins that push directly on the part to eject it. There are several types of injection mold ejector pins, including:

- Straight Pins: The most common type, used for general-purpose applications.

- Stepped Pins: Feature a smaller tip and a wider body, providing greater strength to resist buckling under high force.

- Blade Ejectors: Have a rectangular cross-section to distribute force along thin features like ribs, preventing damage.

- Ejector Sleeves: Hollow pins that fit over a core pin, ideal for ejecting round bosses or posts by applying uniform force around the feature.

- Ejector Plates: The heart of the system is the ejector plate injection molding assembly, which holds all the ejector pins injection molding. It consists of an ejector plate and an ejector retainer plate, which move together as a single unit to actuate the pins.

- Return Pins: After ejection, the entire ejector plate assembly must retract. Return pins are a critical safety feature that pushes the assembly back into position as the mold closes, preventing a catastrophic collision between the ejector pins and the other mold half.

- Stripper Plates: For parts that are delicate, thin-walled, or require a flawless cosmetic surface, a stripper plate is often used. This plate is machined to match the part’s perimeter and pushes on the entire outer edge, “stripping” it from the core with uniform force. This method eliminates pin marks and reduces stress, preventing warpage.

- Air Ejection: A “touchless” method that uses a blast of compressed air to push a part out of the mold. Air ejection is the premier choice for optically clear parts, food-grade containers, or lightweight components that could be damaged by mechanical contact.

Choosing the Right Ejection Method

Selecting the optimal ejection strategy requires a holistic analysis of part design, material, and production goals. Key factors include:

- Part Geometry: Simple, robust parts are well-suited for cost-effective ejector pins. Thin-walled parts like cups or containers benefit from the uniform support of a stripper plate. Any part with undercuts will require more complex actions like lifters.

- Surface Finish Requirements: If minor witness marks from pins are acceptable on non-cosmetic surfaces, pins are the most economical choice. However, for high-gloss products or clear parts where marks are unacceptable, a stripper plate or air ejection is required.

- Cycle Time and Cost: For low-volume production, simple pin ejection is the most pragmatic choice due to its low cost. In high-volume applications, a more expensive stripper plate can provide a strong return on investment by enabling faster cycle times and reducing scrap rates.

- Material Properties: Rigid materials can typically withstand the force of pins, while softer, flexible materials may require the gentle, distributed force of a stripper plate or air ejection to prevent damage.

| Ejection Method | Ideal Part Geometry | Surface Finish Impact | Key Advantage |

| Ejector Pins | Simple to moderately complex shapes, robust walls | Leaves visible witness marks | Simple, versatile, and cost-effective |

| Stripper Plate | Thin-walled containers, cups, lids | No marks on part surface; ideal for cosmetic parts | Uniform force prevents warpage and damage |

| Air Ejection | Very delicate, lightweight, or flexible parts | No contact, no marks; best possible surface finish | Gentle, non-contact ejection for sensitive parts |

Common Ejection Problems and Solutions

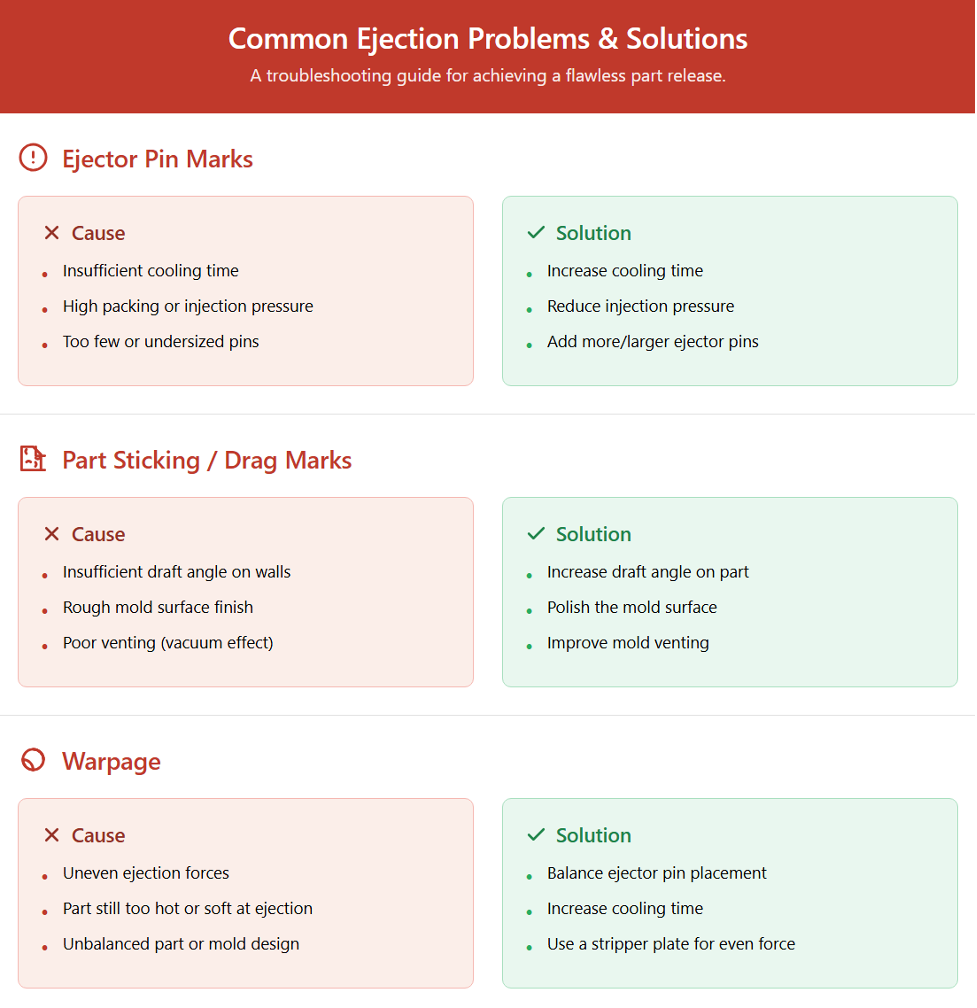

Even with a well-chosen system, defects can occur. Here are some common issues and their solutions:

- Ejector Pin Marks: These are visible impressions on the part caused by excessive localized force.

- Cause: Insufficient cooling time, high packing pressure, or too few/small pins.

- Solution: Increase cooling time, reduce injection pressure, and add more or larger pins to better distribute the force on robust, non-cosmetic areas.

- Part Sticking or Incomplete Ejection: This happens when the part adheres to the mold, causing drag marks or scratches.

- Cause: Insufficient draft angle (taper on the part walls), a rough mold surface, or over-packing the part with plastic.

- Solution: Increase the draft angle on the part design, polish the mold surface, and reduce injection pressure. Improved mold venting is also critical, as vents allow air to enter behind the part, breaking the vacuum seal that causes sticking.

- Warpage: This is any unintended twisting or bending of the part after ejection.

- Cause: Unbalanced ejection forces that physically bend the part as it is pushed out, especially if it is not yet fully rigid.

- Solution: Ensure ejector pins are placed symmetrically to balance forces. For parts prone to warping, using a stripper ejector is a superior solution that provides inherently uniform support. Increasing cooling time also ensures the part is stiff enough to resist deformation.

HordRT’s Approach to Ejection System Design and Injection Molding

Achieving a flawless ejection process begins long before the mold is built. The most successful outcomes rely on a collaborative Design for Manufacturability (DFM) process between the product designer and the mold maker.

Leading manufacturing service providers like HordRT leverage this proactive approach, integrating advanced technologies to optimize every stage of production. By combining high-precision electric injection molding machines with innovations like rapid magnetic mold clamping systems, an efficient manufacturing ecosystem is created. In this context, a perfectly optimized mold ejector system is not just a component but a key enabler of the high-speed, automated, and data-driven manufacturing that modern markets demand.

Conclusion

The ejection system is a foundational element of the injection molding process, with a direct impact on part quality, efficiency, and profitability. A successful outcome depends on a proactive approach that prioritizes Design for Manufacturability (DFM), including adding proper draft angles and vents to the part design.

The choice between ejector pins injection molding, a stripper plate, or air ejection requires a careful analysis of the part’s geometry, material, and cosmetic requirements. By collaborating with manufacturing experts early in the design process, companies can prevent ejection-related defects at their source, ensuring a robust and efficient molding process that delivers high-quality parts every time.